The dates and location for HECO’s 2024 RPM Symposium are set for Oct. 1-2 in Kalamazoo, Michigan. As we eagerly await that event, there is still a wealth of knowledge available from our 2023 event in Kentucky to share.

“APOLLO: Reliability-Driven IoT,” a breakout session presented by HECO’s Senior Program Manager Luke Clark, is a great example and well worth your time if you are investigating sensor integration or upgrades for your industrial equipment.

About Our Speaker & RPM

Clark has more than a decade of experience in Enterprise Asset Management, IoT (Internet of Things), asset health and reliability, and maintenance planning and scheduling. He has participated in the training, configuration, integration, and operation of multiple platforms and processes across many industries.

He earned a bachelor’s degree in technology and organizational leadership from Purdue University. A member of the HECO team since 2022, Clark works to identify reliability value by utilizing Predictive maintenance for HECO clients and is responsible for partner relations, strategic execution, pipeline development, and project management.

Clark was one of HECO’s many speakers at the 2023 RPM Symposium.

Offered at no cost to attendees, HECO’s RPM (Reliability Process & Maintenance) Symposium, is a Midwest-based annual conference event where maintenance professionals and technicians can network and learn about reliability, maintenance best practices, electric motor-driven powertrains, IIoT (Industrial Internet of Things) Solutions, methods for increasing reliability in industrial facilities, and much more.

On-Demand Learning

APOLLO is HECO’s approach to service-based IoT and remote condition monitoring.

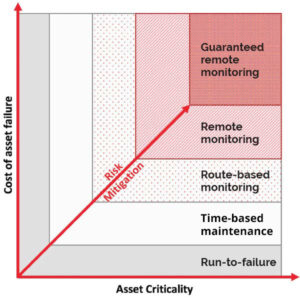

“This is a full-blown solution, so it doesn’t make sense for every piece of equipment you have,” Clark said. “We really recommend APOLLO for your most critical needs, roughly the top 10% of your equipment.”

Determining if APOLLO is a good fit for your assets requires evaluating your maintenance approach and, ultimately, how committed your company is to working towards a culture of reliability.

In the video, Clark discusses how to:

- Distinguish maintenance from reliability.

- Take an industrial approach to IoT applications.

- Avoid the three types of IoT failures.

- Differentiate reliability terms and philosophies.

- Select sensors and stay up-to-date with technology.

- Assess asset criticality and the need for sensors.

- Utilize HECO’s approach to service-based IoT.

Learn all of these and more in Clarks’ 38-minute presentation.

All Systems Go

HECO has worked in the Predictive maintenance industry for more than 30 years and the Industrial IoT (IIoT) field for more than 15 years.

“We treat APOLLO as a service,” Clark said. “We don’t want to sell you sensors that don’t work or fit your business model. We want to be sure that you’re actually getting the end result. What matters is that you’re getting the data that you need to make decisions to better improve your equipment.”

At HECO, the goal is to understand the “what” and “why” of your equipment, its performance, and what the best solution is for your needs and goals.

Registration for the 2024 RPM Symposium is open now. Visit www.rpmsymposium.com to register free of charge before Sept. 15, 2024; after that date, the cost will be $150 per person to attend.

Be sure to watch Luke Clark’s 2023 session and contact us to let us know what you’d like to learn at this year’s RPM Symposium or discuss your electric motor and rotating equipment needs and challenges.